Thread Tolerances

The ISO metric system (International Organization for Standardization) is an international standard for measuring and defining thread fit tolerances...

The ISO Metric System

The International Metric System (ISO) is a set of globally used standards ensuring that production materials meet quality, safety, and compatibility specifications...

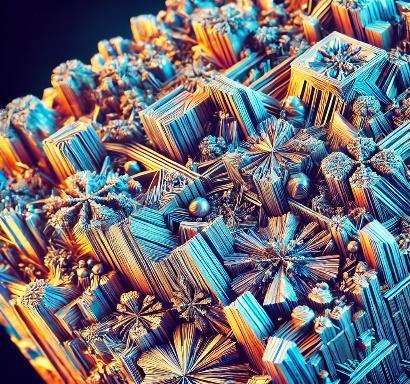

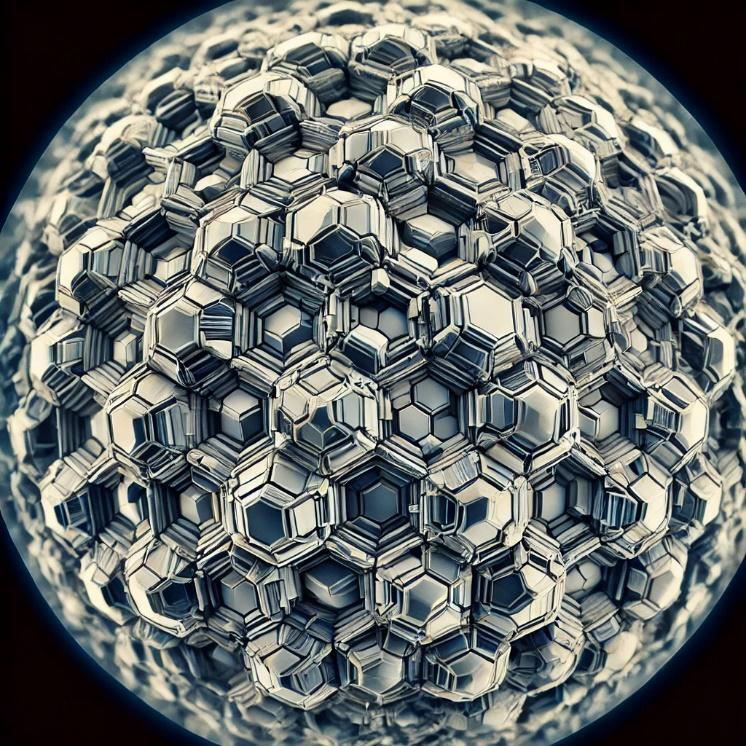

Metal Alloys

The International Organization for Standardization (ISO) provides specifications for a wide range of materials, including metals and their alloys...

Screw Production Materials

The ISO metric system is an international standard for screws that defines dimensions, tolerances, and material specifications...

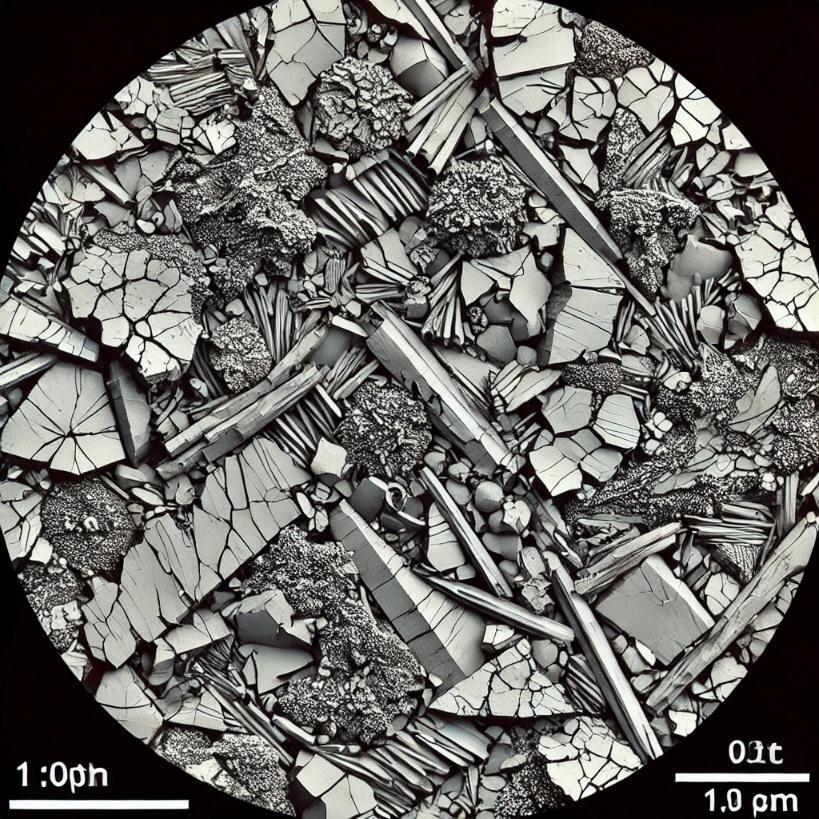

Iron Alloys

Iron alloys, commonly known as steels and cast irons, are fundamental materials in the mechanical and manufacturing industries...

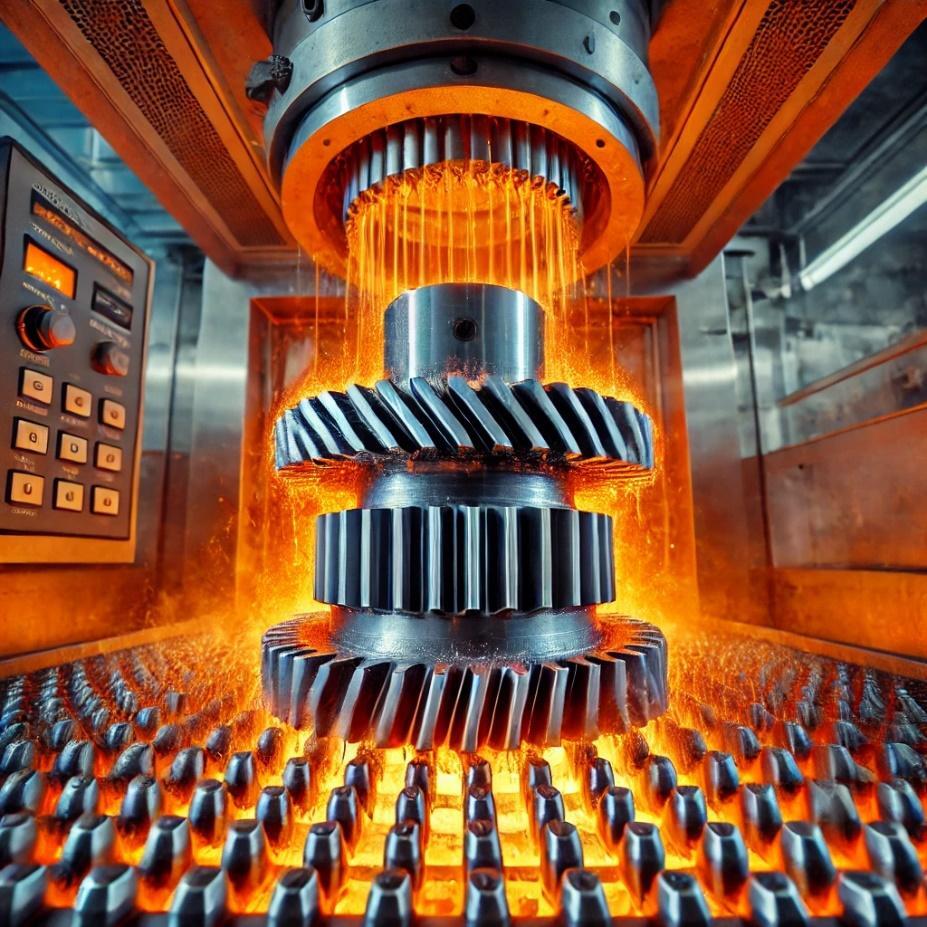

Carbon Steel Heat Treatments

Carbon steels are widely used in the mechanical industry due to their excellent mechanical properties and versatility...

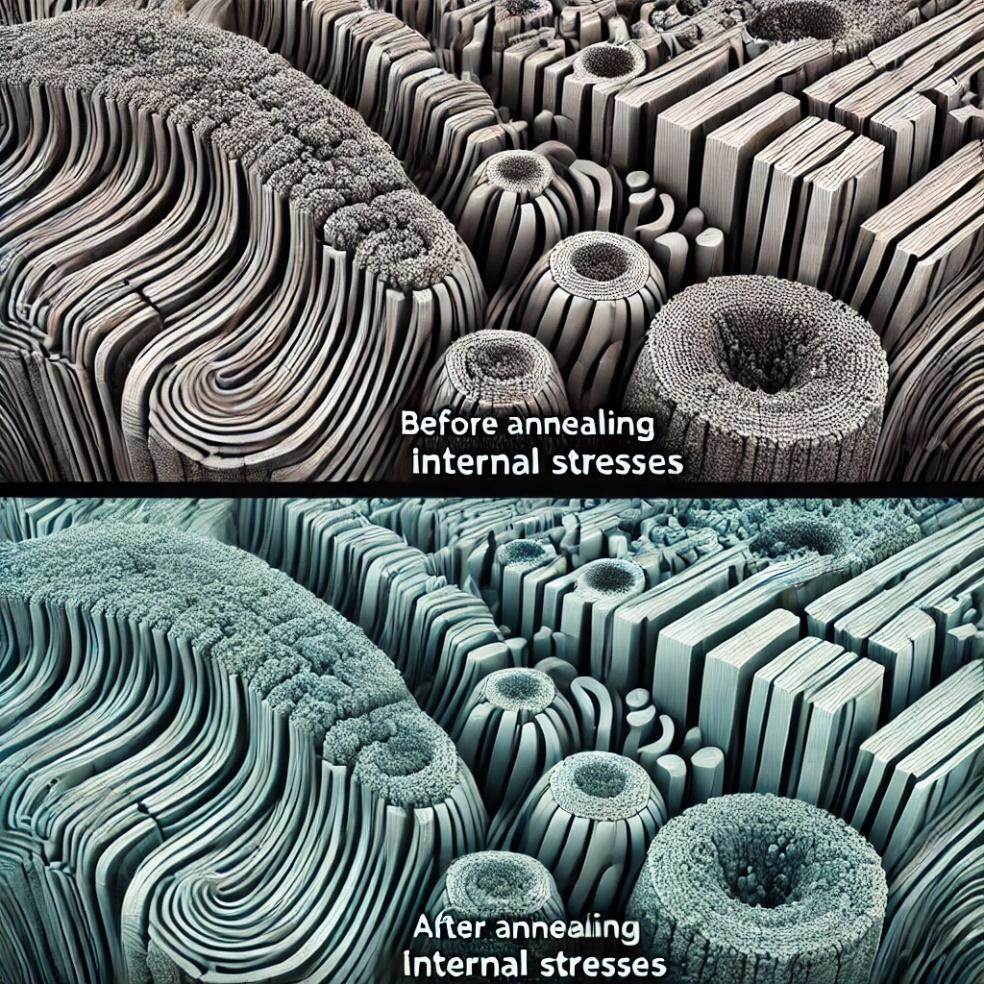

Stress Relief

Stress relief treatments, also known as relaxation treatments, are thermal processes applied to metallic materials to reduce internal stresses caused by machining, welding, or uneven cooling...

Annealing

Annealing is a heat treatment process used to alter the physical and sometimes chemical properties of a material to increase its ductility and reduce its hardness, making it more workable...

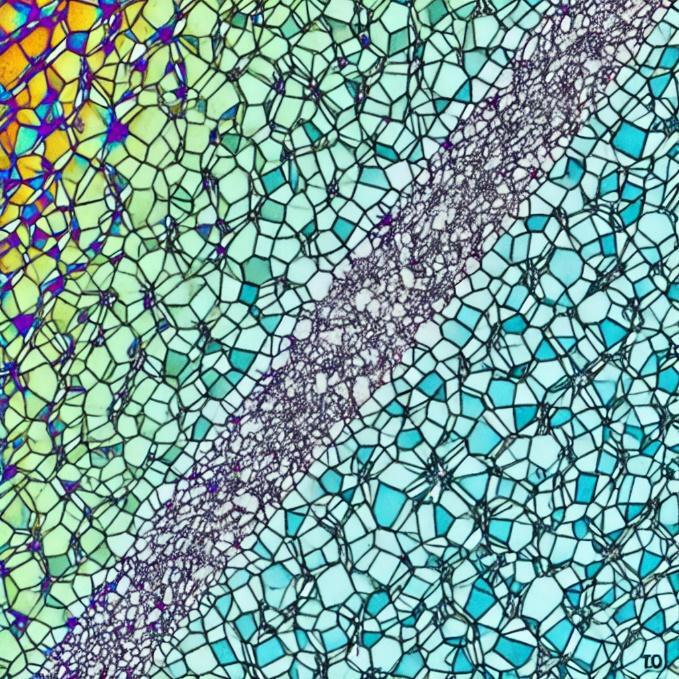

Normalization

Normalization is a heat treatment applied to steels to improve their crystalline structure and optimize mechanical properties...

Surface Hardening

Surface hardening is a heat treatment used to harden the surface of metal components, improving their wear resistance, fatigue strength, and deformation resistance...

Carburizing

Carburizing is a heat treatment process used to increase the surface hardness of steels. This process involves introducing carbon onto the material's surface by heating it in a carbon-rich environment...

Nitriding

Nitriding is a thermochemical treatment used to enhance the surface properties of steels and other ferrous alloys...

Carbon Steel Classification

Carbon steels are one of the most widely used metallic alloys in the mechanical and metallurgical industries...

Stainless Steels

Stainless steels are a family of metal alloys characterized by their resistance to corrosion...

Cast Iron

Cast iron is a ferrous alloy

containing a high percentage of carbon, usually above 2%, along with silicon and other trace elements...

Brass

Brass is a metal alloy primarily composed of copper and zinc, with varying percentages of each element determining the specific properties of the alloy...

Copper

Copper is a reddish-brown metal known for its high electrical and thermal conductivity...

Aluminium

Aluminum is a lightweight, ductile, and corrosion-resistant metal widely used in various industrial sectors...

Titanium

Titanium is a lightweight and strong metal, known for its excellent corrosion resistance and extremely favorable strength-to-weight ratio...

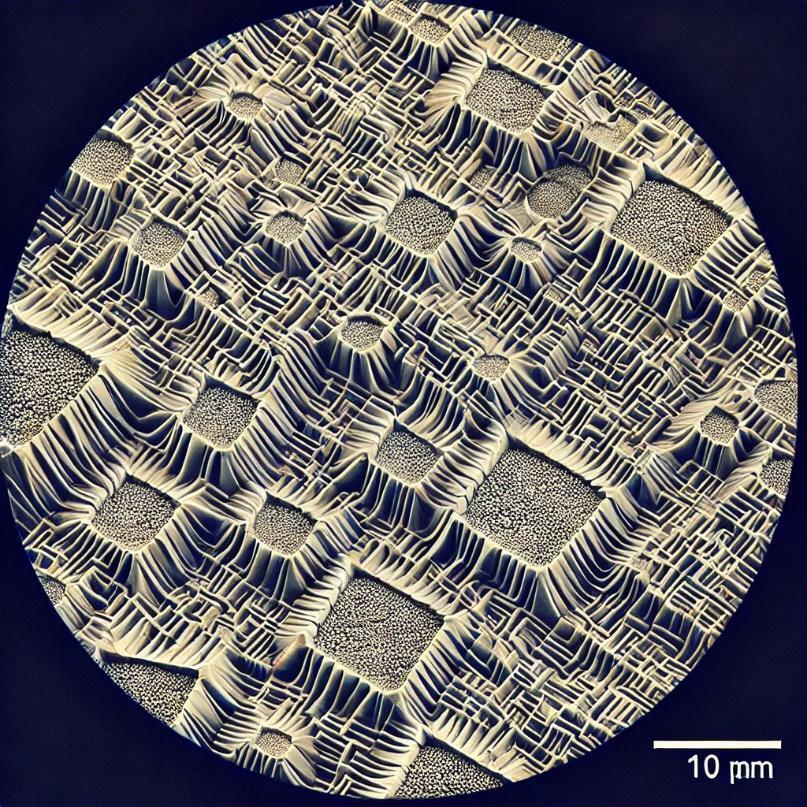

Screw Manufacturing Techniques

The ISO Metric System (International Organization for Standardization) is an international standard that defines the dimensions and tolerances of mechanical components such as screws, nuts, and washers...

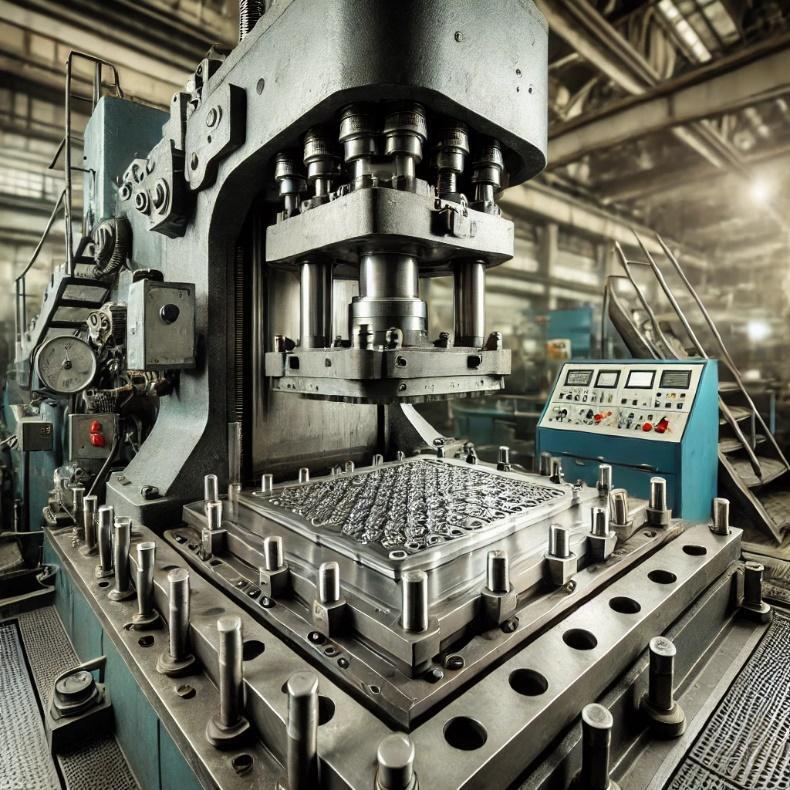

Stamping

The stamping process for the production of screws and bolts is fundamental in the mechanical industry.

Hot Forging

Hot forging is a widely used metalworking technique in the mechanical industry for producing components with complex geometries and high mechanical properties...

Cold Forging

Cold forging is a metal plastic deformation technique that takes place at room temperature or slightly above, without heating the material...

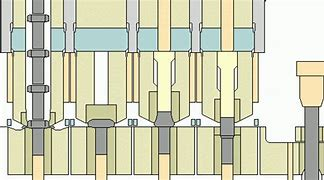

Stamping and Extrusion Techniques

Stamping and extrusion techniques are plastic deformation processes used in the mechanical industry to produce components with complex shapes and superior mechanical properties...

Rolling

Thread rolling is a cold-forming process used to produce threads on screws and bolts...

Punching

Punching is a mechanical processing technique used to cut or shape materials using a punch and die...

Chip Removal Machining

Machining by chip removal is a manufacturing technique that involves the removal of material from a raw workpiece to obtain the desired shape...

Turning

Turning is one of the most widely used machining processes for chip removal, employed to create cylindrical, conical, or profiled surfaces on a workpiece...

Drilling

Drilling is one of the fundamental techniques in machining by chip removal, used to create cylindrical holes in solid materials...

Milling

Milling is one of the most versatile techniques in chip removal mechanical processing, used to create flat surfaces, grooves, complex profiles, and pockets on a wide variety of materials...

Mechanical Properties of bolts and nuts

The ISO Metric System (International Organization for Standardization) is an international standard that defines the dimensions and tolerances of mechanical components such as screws, nuts, and washers...

Properties of Metric Threaded Bolts and Studs

The ISO metric system (International Organization for Standardization) is one of the most widely used measurement systems...

Mechanical and Physical Properties of Bolts

Bolts are essential fastening elements in many mechanical and structural applications. They are designed to...

Breaking Loads For Bolts With Reduced Load Capacity

Bolts are essential components in many mechanical and structural applications...

Breaking Loads for Screws

Bolts are essential components in many mechanical and structural applications. However, the shape and design of bolts can significantly affect...

Structural Fasteners

Structural fasteners represent a critical category of fastening elements used in construction and large infrastructure projects...

Read more about →